Racing to Meet the Challenges of Electrification

By Rick Fennelly, Marketing Manager,

Allegro MicroSystems, LLC

Governments around the world, including the European Union and United States, have placed mandatory fuel economy standards on combustion engines to reduce emissions. These initiatives will require innovative advances in technologies, driving the demand for increased efficiencies, placing additional burden on design teams, and potentially impacting development cycle times.

An area of focus will be to develop strategies for reducing load on the vehicle engine. Roughly 15% of the energy from fuel is used to move a vehicle down a road—the balance is consumed by engine and driveline inefficiencies.1 Therefore, reducing load will allow the engine to work more efficiently and thereby contribute to a reduction in fuel consumption. The challenge is in providing equal or enhanced performance while maintaining or improving the overall driving experience. To achieve this goal, there is a growing demand for the electrification of cars where electrical motors are being used in place of traditional belt-driven systems. To that end, the world market for electric motors in automotive applications is growing at a compound annual growth rate (CAGR) of 4.7%.2 Specifically, the market for DC brushless motors in automotive applications is predicted to outpace by twice the market growth for other motor types with a unit CAGR of 6.3% from 2014 to 2019.2

Improving these systems with electrical solutions has created new challenges for Tier 1 manufacturers, where these new innovations require an increase in staff and development time. Designers are looking for methods to reduce the development cycle while maintaining high performance goals. As a result, BLDC motor control is increasing in market share. For example, a vehicle water pump which is traditionally belt driven has transitioned to an electrical motor. This is needed for start-stop systems which improve efficiency and reduces emissions. To keep engine coolant circulating, an electrical motor replaces the belt driven pump. Other systems affected by engine start-stop systems requiring conversion to BLDC motors include hydraulic and oil pumps.

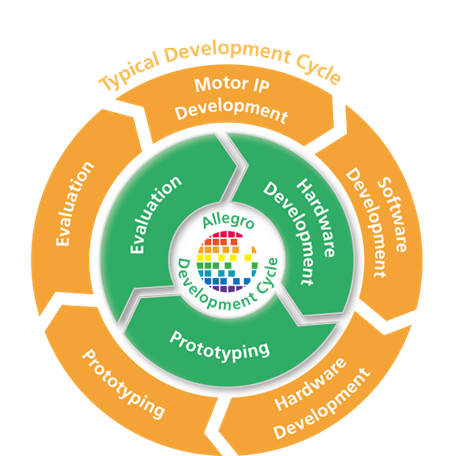

A new generation of motor driver ICs that up-integrate complex commutation algorithms simplifies the engineering design of a BLDC motor control system. Companies such as Allegro MicroSystems, LLC have developed proven algorithms for trapezoidal and sinusoidal control for both sensor and sensorless BLDC motors so that engineers are not challenged with writing and validating software, helping them to meet aggressive timelines.

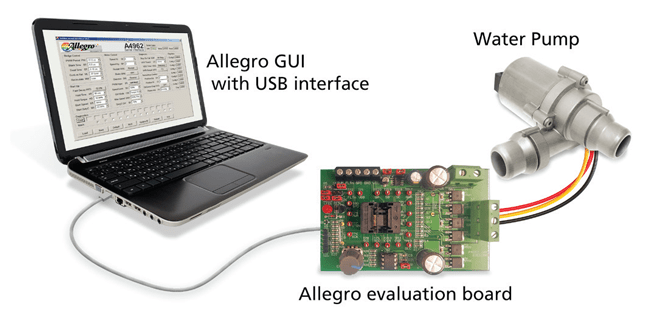

In many of the advanced Allegro motor drivers, the commutation algorithm is integrated into the IC. An easy-to-use software GUI passes parameters via USB to the on-chip EEPROM, where they are used by the on-chip algorithm. This enables an engineer with no software programming experience to design and validate a motor system, breaking the time-consuming cycle of software development and validation. Innovations like these lower the workload on the microcontroller, allowing the developer to specify a less powerful (hence less expensive) device. For some applications, it’s even possible to eliminate the microcontroller altogether, providing additional cost savings.

Allegro offers highly integrated gate driver ICs, such as the A4960 and A4962 sensorless BLDC drivers. These devices incorporate on-chip sensorless trapezoidal commutation, as well as high-power gate drive to enhance the external inverter bridge. Up-integration of functions usually programmed in a microprocessor make these devices capable of standalone operation by integrating closed-loop speed or torque control. Comprehensive diagnostics feed back to the ECU, providing detail about synchronization, overvoltage, undervoltage, or shorted MOSFET conditions. Single wire operation can be achieved by sending fault diagnostics over the PWM input.

The highly versatile algorithms offer a wide range of programming parameters, enabling engineering to reuse hardware for different products by simply modifying parameters within on-chip EEPROM. This makes Allegro’s programmable motor drivers easy to use and reuse for a wide variety of motors, loads, and applications. Up-integrated ICs, along with Allegro programming tools, simplify workflow and shorten design cycles, promoting customer innovation. These solutions enable manufacturers to achieve demanding fuel economy standards through electrification while also providing improved performance to the end customer.

Looking forward, vehicle autonomy will drive the continued trend for the electrification of vehicles. IHS Automotive is projecting sales of close to 600,000 autonomous vehicles by 2025. Further, IHS expects a 43% compound annual growth rate (CAGR) between 2025 and 2035 to nearly 21 million autonomous vehicles.3 This growth will spur an increasing demand for electrical motor control where system integration will continue to drive designers to look for innovative solutions. Additionally, autonomous vehicles will need to incorporate redundant systems as a matter of safety to consumers where the automobile will be making an increasing number of decisions for the driver—or with some functions, may remove the driver from the decision-making process entirely.4

Companies like Allegro MicroSystems, LLC are currently manufacturing and will continue to develop future products meeting the ISO 26262 safety standard. The Automotive Safety Integrity Level (ASIL) defined by the ISO 26262 standard contains requirements for both the development process and for the design of safety-related electronic systems in road vehicles. This requirement reaches IC component suppliers by requiring more content integrated into existing solutions and the capability of running diagnostics and communicating their status.5 These innovative products help engineers simplify their designs and design cycles by providing supervisory and verification functions up-integrated within the IC.

As the automotive market continues to innovate to meet the demand for better performance and improved fuel economy, and with the expectant growth of the autonomous vehicle market, electrical motor systems will continue to play a growing role in providing more efficient alternatives to mechanical systems. As such, design engineers will be looking for cutting-edge solutions that streamline their design process while providing value added features that help them develop cost-effective competitive products. Companies such as Allegro MicroSystems, LLC have recognized this need and remain at the forefront for providing innovative new products that will meet the demanding requirements for the automotive future.

- 1 http://www.consumerenergycenter.org/transportation/consumer_tips/vehicle_energy_losses.html

- 2 IHS Technology. The World Market for Electric Motors in Automotive Applications – 2015

- 3 http://news.ihsmarkit.com/press-release/automotive/autonomous-vehicle-sales-set-reach-21-million-globally-2035-ihs-says

- 4 /en/Design-Center/Technical-Documents/General-Semiconductor-Information/Functional-Safety-Challenges-Automotive-Supply-Chain By Lisa Clark, Functional Safety Manager, Allegro MicroSystems, LLC and Scott Milne, Product Line Director – Linear and Angle Sensor ICs, Allegro MicroSystems, LLC

- 5 IHS Technology. The World Market for Electric Motors in Automotive Applications – 2

Article published in Hanser Automotive, March 2017. Reprinted with permission.