Voltage Isolation in Variable Frequency Drives

By Shaun Milano,

Allegro MicroSystems, LLC

Abstract: For most engineers, it can be daunting to design a Variable Frequency Drive (VFD) that complies with international standards for voltage isolation. When is reinforced insulation required? When is basic or supplemental insulation sufficient? Despite the complexity of the standards, there are some simple guidelines to help the designer understand the type of isolation that will be required. This applications note, while not designed to be a comprehensive analysis of voltage isolation standards, introduces various Allegro current sensor integrated circuit (IC) packages that can be used to achieve high isolation ratings that meet industry standards.

Introduction

In this application note, a VFD is used as an example system that must meet isolation standards through the use of insulation layers. Many of these same isolation concepts will apply to almost any system that has high voltage control components and a user interface. The basic assumption is that all equipment should be designed with safety clearly in mind—to protect users from electric shock1. Most standards require the user be protected from electrical shock by two levels of protection, or a single layer of insulation protection that is considered to be reinforced2. A few terms should be defined when discussing insulation and are provided below.

- basic insulation. Insulation to provide basic protection against electric shock.

- supplementary or supplemental insulation. Independent insulation applied in addition to basic insulation in order to reduce the risk of electric shock.

- double insulation. Insulation comprising both basic insulation and supplementary isolation.

- reinforced insulation. Single insulation system that provides a degree of protection against electric shock equivalent to double insulation under conditions specified by a standard.

The definition of reinforced insulation is a common cause of confusion for many system designers, as it requires familiarity with a safety standard. This need not be the case, by understanding that only double or reinforced insulation is sufficient to protect a user against electric shock. While there are many UL and IEC specifications which define a shock hazard voltage at slightly different levels, a good rule of thumb is any voltage exceeding 42.4 Vrms or 60 VDC poses a risk. Voltages lower than this do not pose serious risk for electrical shock in most cases, and are referred to as extra-low voltage supply systems. For example, in the United States, the telephone system, from its invention, was limited to 50 VDC in order to protect users from electrical shock and remains 50 VDC to this day. These basic rules help us as we move to the VFD architecture.

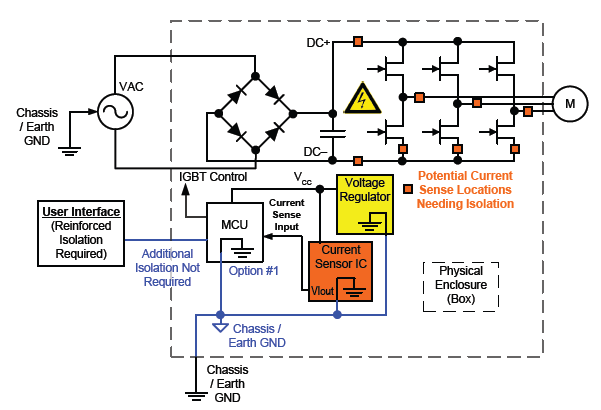

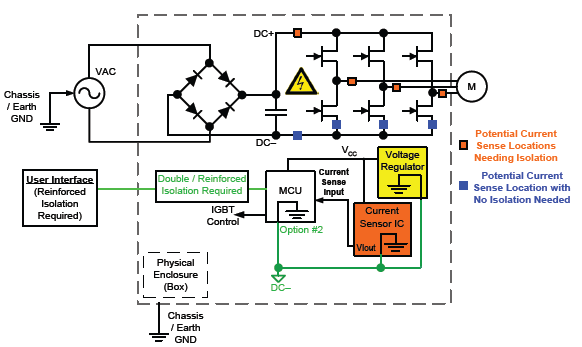

A VFD will rectify an AC mains voltage to a DC voltage, and use that DC voltage to drive a motor. Figure 2 and Figure 3 use a standard three-phase VFD topology with IGBTs used to switch the voltage to the phases of the motor. The IGBTs are controlled by the system microcontroller (MCU). The current feedback provided by the current sensor(s) is also fed into the MCU and is part of the motor control loop. The VFD is controlled via a user interface that is normally connected to digital I/O pins of the MCU. The rectified voltage levels from DC+ to DC– range from 200 to 1000 VDC. While VFDs in this voltage range are considered “Low Voltage” per industry nomenclature, these voltage levels pose serious risk of electrical shock and require compliance to safety standards. These voltage levels generally require that double or reinforced insulation is achieved (per industry standards) between the user interface and other electronics in the physical enclosure. This insulation is required to achieve the isolation rating per the standard to which it is certified, so when a device or system is certified, it is given an isolation rating, not an insulating rating.

A common industry standard is UL60950-1 edition 2. While this standard was designed for information technology equipment, its stringent requirements have made it a benchmark standard for many different equipment and component designs. Common component-level standards include IEC60747-5-2 and UL1577, and common systemlevel standards beyond UL60950-1 also include 60730-1, 62368-2 and 61010-1. Allegro has several IC solutions that can provide the isolation required for VFD applications.

Allegro Isolation Solutions

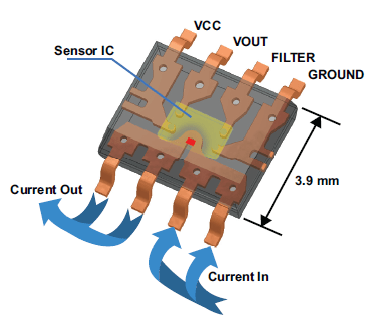

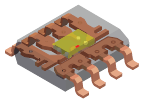

Allegro current sensor ICs are unique in that they are fully integrated. The current will travel into and out of the sensor IC package on one side, and the signal leads are on the other. This provides creepage and clearance between the primary current (high-voltage) side and the signal leads (low-voltage side). An SOIC8 standard footprint IC from Allegro is illustrated in Figure 1. Allegro surfacemount current sensor ICs can be used in any of the common sensing locations in VFDs, for currents up to 40 A continuous, with peaks up to 65 A or even higher, depending on the printed circuit board (PCB) design. An applications note on package thermal performance for DC and transient currents is available on the Allegro website at:

Flip chip assembly technology provides spacing between the sensor IC and current-carrying conductor in the package, which provides the insulation required to achieve high-voltage isolation ratings under UL and IEC specifications. A short video explaining some of the proprietary packaging techniques used by Allegro to achieve high isolation ratings in these small footprint surface-mount current sensor IC packages is available on the Allegro website at:

VFDs require different isolation ratings depending on system architecture. Figure 2 and Figure 3 show two typical methods for achieving double or reinforced isolation in VFDs. First, let’s assume that the equipment is correctly wired and plugged into the AC mains, and that the motor is properly connected and grounded safely so as not to introduce any further risk of electric shock. Under this assumption, we can deal strictly with the insulation required between the user interface and the circuits internal to the physical enclosure.

Figure 1: Allegro Current Sensor IC

Option #1 (GND Referenced)

In this configuration, shown in Figure 2, the MCU is referenced to Earth GND, and therefore, the user interface would not normally be subjected to a voltage level that posed a risk of electric shock. The MCU would be provided with 3.3 or 5 V nominal VCC from a regulator that is also referenced to GND.

Notice, however, that the output signal of the current sensor is also connected to the MCU. The internal conductor of the sensor IC is connected to dangerous voltage levels in the bridge driving the motor. If the user interface is directly connected to digital I/O pins of the MCU, the current sensor IC is now required to provide double or reinforced isolation as the only means of protecting the user. No matter where the current is sensed in Figure 2, using a chassis or earth GND topology, the current sensor will need to provide reinforced isolation. The reason is that if the current sensor was to fail, the MCU would also fail and potentially expose the user to a shock hazard via the user interface. Allegro current sensor ICs are available that provide reinforced isolation ratings up to 800 VDC, which are well suited for this topology.

Figure 2: VFD Basic Diagram (MCU Referenced to GND)

Option #2 (High Voltage Referenced)

Another common VFD topology, shown in Figure 3, has the MCU referenced to a high-voltage potential, either the DC– or DC+ rectified voltage. The user interface therefore would also be exposed to this voltage potential if directly connected to the MCU, posing a risk of electrical shock. For this reason, double or reinforced isolation between the user interface and MCU circuit is required for protection, as illustrated in Figure 3.

Since double or reinforced isolation is required between the MCU and user interface, the current sensor only needs to provide functional voltage isolation to protect the MCU. This is easily accomplished with basic insulation available in many Allegro current sensor ICs. Though, with this topology, some sensing locations do not require any isolation, as shown in Figure 3, due to being at a similar potential to the MCU.

Finally, as previously mentioned, in VFDs, the user interface to the MCU is generally composed of simple digital I/O lines, so the reinforced insulation is provided by digital or opto-isolators with a reinforced isolation rating. Every I/O pin between the MCU and the user interface requires this protection, and therefore several opto-isolators may be required.

By employing the GND referenced topology of Figure 2 with reinforced Allegro current sensor ICs, the opto-isolators can be removed; however, it is then required to isolate the MCU from the drive signals to the IGBTs.

Figure 3: VFD Basic Diagram (MCU Referenced to High Voltage)

No matter which VFD topology is used, Allegro has patented several technologies that achieve either basic or reinforced isolation in small footprint current sensor semiconductor packages to meet the application needs. Furthermore, Allegro offers a diverse portfolio of current sensor ICs for VFD (and other high-voltage) applications with different integrated features and accuracy levels. Each of Allegro’s patented current sensor ICs are certified to stringent industry standards, such as UL/TUV 60950-1 and UL1577.

Table 1 summarizes the surface-mount package options available from Allegro and their associated standard-certified isolation levels. All components in Table 1 are certified to the IEC/ UL60950-1 specification.

The summary table includes options for a standard SOIC8 package footprint and a wide body SOIC16 package footprint. The different isolation ratings are derived from internal or external construction techniques that were designed to comply with the UL or TUV specifications used to certify the ICs. Notice that all packages provide a basic isolation rating that enables high operating voltages. Allegro solutions in the SOIC16 wide body (MA) package can provide a reinforced rating on DC buses as high as 800 VDC, and a basic rating up to 1550 VDC.

| Package (Code) |

Isolation Rating Vrms |

Basic Working Voltage Vpk |

Reinforced Working Voltage Vpk |

Package Drawing | |

| SOIC8 (LC) |

2400 | 420 | 164 |  |

|

| SOIC16W (LA) |

3600 | 870 | not available |

|

|

| SOIC16W (MA) |

4800 | 1550 | 800 | ||

A summary of the surface-mount package current sensor IC solutions offered by Allegro, along with their isolation ratings, is available at:

See individual datasheets for the exact basic and reinforced isolation ratings, UL or TUV standard, and detailed package drawings.

Additional applications notes, frequently asked questions, and product information can also be found at www.allegromicro.com.

1 UL60950-1 Introduction: Section 0.1 “General principles of safety”.

2 Definitions are taken from UL60950-1 “Definitions” section.