Latching Switch Hall-Effect IC Basics

There are four general categories of Hall-effect IC devices that provide a digital output: unipolar switches, bipolar switches, omnipolar switches, and latches. Latching switches are described in this application note. Similar application notes on unipolar switches, bipolar switches, and omnipolar switches are provided on the Allegro™ website.

Latching Hall-effect sensor ICs, often referred to as "latches," are digital output Hall-effect switches that latch output states. Latches are similar to bipolar switches, having a positive BOP and negative BRP, but provide tight control over switching behavior. Latches require both positive and negative magnetic fields to operate. A magnet presenting a south polarity (positive) magnetic field of sufficient strength (magnetic flux density) will cause the device to switch to its on state. When the device is turned-on it latches the state and remains turned-on, even if the magnetic field is removed, until a north polarity (negative) magnetic field of sufficient strength is presented. When the negative field is presented, the device is turned-off. It latches the changed state and remains turned-off, even if the magnetic field is removed, until a south polarity (positive) magnetic field of sufficient strength is again presented.

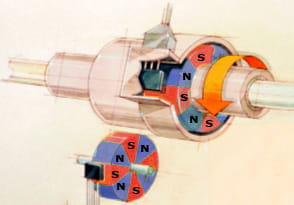

Applications for detecting the position of a rotating shaft are shown in figure 1. The multiple magnets are incorporated into a simple structure referred to as a "ring magnet," which incorporates alternating zones of opposing magnetic polarity. The IC package adjacent to each ring magnet is the Hall latch device. When the shaft rotates, the magnetic zones are moved past the Hall device. The device is subjected to the nearest magnetic field and are turned-on when a south field is opposite, and turned-off when a north field is opposite. Note that the branded face of the device is toward the ring magnet.

Figure 1. Two latched device applications using ring magnets. The ring magnets have alternating N (north) and S (south) polarity zones, which are rotated past the Hall devices, causing them to turn on and off.

Magnetic Switchpoint Terms

The following are terms used to define the transition points, or switchpoints, of Hall switch operation:

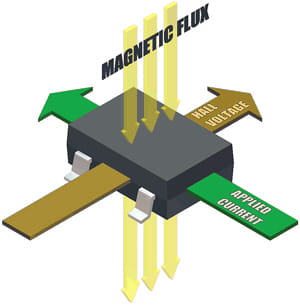

Figure 2. The Hall effect refers to the measurable voltage present when an applied current is influenced by a perpendicular magnetic field.

- B − The symbol for Magnetic Flux Density, the property of a magnetic field used to determine Hall device switchpoints. Measured in gauss (G) or tesla (T). The conversion is 1 G = 0.1 mT.

B can have a north or south polarity, so it is useful to keep in mind the algebraic convention, by which B is indicated as a negative value for north-polarity magnetic fields, and as a positive value for south-polarity magnetic fields. This convention allows arithmetic comparison of north and south polarity values, where the relative strength of the field is indicated by the absolute value of B, and the sign indicates the polarity of the field. For example, a − 100 G (north) field and a 100 G (south) field have equivalent strength, but opposite polarity. In the same way, a − 100 G field is stronger than a − 50 G field.

- BOP − Magnetic operate point; the level of a strengthening magnetic field at which a Hall device switches on. The resulting state of the device output depends on the individual device electronic design.

- BRP − Magnetic release point; the level of a weakening magnetic field at which a Hall device switches off (or for some types of Hall devices, the level of a strengthening negative field given a positive BOP). The resulting state of the device output depends on the individual device electronic design.

- BHYS − Magnetic switchpoint hysteresis. The transfer function of a Hall device is designed with this offset between the switchpoints to filter out small fluctuations in the magnetic field that can result from mechanical vibration or electromagnetic noise in the application. BHYS = | BOP − BRP |.

Typical Operation

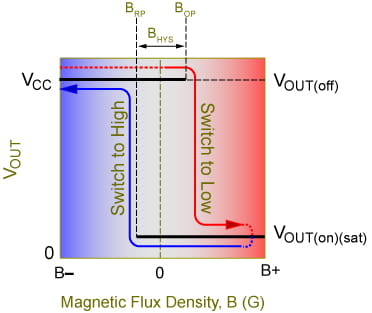

The switchpoints of latching sensor ICs are symmetrical around the neutral field level, B = 0 G, as shown in figure 3. The switchpoints are at equal field strengths, but at opposite polarities. For example, if the operate point, BOP, is 85 G (a positive value indicating south polarity), the release point, BRP, is − 85 G (a negative value indicating north polarity). Latching the latest state prevents the devices from switching while subject to weak fields.

A latching switch turns on in a strong south polarity field, and the resulting output signal is logic low (at the output transistor saturation voltage, VOUT(sat), usually <200 mV). A latching switch turns off in a strong north polarity field, and the resulting output signal is at logic high (up to full supply voltage, VCC). Because the switched state is latched, these devices do not switch while the magnetic field is in the switchpoint hysteresis range, between BOP and BRP. Because the 0 G point must be crossed before switching occurs in either direction, the hysteresis range is relatively wider than for other types of Hall switches.

Figure 3. Latching switch output characteristics. The device output switches to logic low in the presence of a strong south polarity field, and switches to logic high in a strong north polarity field. In a weak field, the latch does not change output state.

Although the device could power-on with the magnetic flux density at any level, for purposes of explanation of figure 3, start at the far left, where the magnetic flux (B, on the horizontal axis) is less positive than BRP or BOP. Here the device is off, and the output voltage (VOUT, on the vertical axis) is high.

Following the arrows toward the right, the magnetic field becomes increasingly positive. When the field is more positive than BOP, the device turns on. This causes the output voltage to change to the opposite state, low.

While the magnetic field remains more positive than BRP, the device remains turned-on, and the output state remains unchanged. This is true even if B becomes slightly less positive than BOP, within the built-in zone of switching hysteresis, BHYS.

Following the arrows back toward the left, the magnetic field becomes less positive and then more negative. When the magnetic field again drops below BRP, the device turns off. This causes the output to change back to the original state.

Magnets

Individual magnets may be used to provide the two opposing magnetic polarities, however, it is usually more cost effective to use ring or strip magnet material. Ring and strip magnets are magnetized with alternating poles with specified spacing. A ring magnet is a toroid- or disc-shaped assembly (see figure 1) with alternating radially- or axially-magnetized poles. A strip magnet is a flat strip with alternating magnetic poles. Ring magnets are available in a variety of materials including ceramic, rare earth, and flexible materials. Strip magnets nearly always utilize flexible materials such as Nitrile rubber binder containing oriented barium ferrite, or higher energy rare-earth materials.

Ring magnets normally are specified as having a number of poles while strip magnets are normally specified in poles-per-inch. A four-pole ring magnet contains two north and two south oriented alternating poles (N-S-N-S) while an 11 pole-per-inch strip magnet has alternating poles spaced on 0.0909-in. centers. A variety of pole spacings are available from magnet manufacturers.

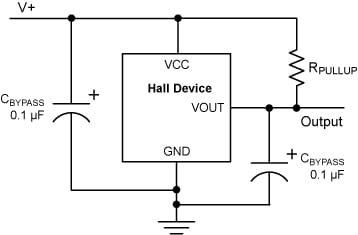

Pull-Up Resistor

A pull-up resistor must be connected between the positive supply and the output pin (see figure 4). Common values for pull-up resistors are 1 to 10 kΩ. The minimum pull-up resistance is a function of the sensor IC maximum output current (sink current) and the actual supply voltage. 20 mA is a typical maximum output current, and in that case the minimum pull-up would be VCC / 0.020 A. In cases where current consumption is a concern, the pull-up resistance could be as large as 50 to 100 kΩ. Caution: With large pull-up values it is possible to invite external leakage currents to ground, which are high enough to drop the output voltage even when the device is magnetically off. This is not a device problem but is rather a leakage that occurs in the conductors between the pull-up resistor and the sensor ICs output pin. Taken to the extreme, this can drop the sensor IC output voltage enough to inhibit proper external logic function.

Figure 4. Typical application diagram.

Use of Bypass Capacitors

Refer to figure 4 for a layout of bypass capacitors. In general:

- For designs without chopper stabilization − It is recommended that a 0.01 µF capacitor be placed the output and ground pins and between the supply and ground pins.

- For designs with chopper stabilization − A 0.1 µF capacitor must be placed between the supply and ground pins, and a 0.01 µF capacitor is recommended between the output and ground pins.

Power-On State

A latch powers-on in a valid state only if the magnetic field strength exceeds either BOP or BRP when power is applied. If the magnetic field strength is in the hysteresis band, that is between BOP and BRP, the device can assume either an on or off state initially, and then attains the correct state at the first excursion beyond a switchpoint. Devices can be designed with power-on logic that sets the device off until a switchpoint is reached.

Power-On Time

Power-on time depends to some extent on the device design. Digital output sensor ICs, such as the latching device, reach stability on initial power-on in the following times.

| Device type | Power-on time |

|---|---|

| Non-chopped designs (such as A1210 family) | <4 µs |

| Chopper-stabilized (such as A1220 family) | <25 µs |

Basically, this means that prior to this elapsed time after providing power, device output may not be in the correct state, but after this time has elapsed, device output is guaranteed to be in the correct state.

Power Dissipation

Total power dissipation is the sum of two factors:

- Power consumed by the sensor IC, excluding power dissipated in the output. This value is VCC times the supply current. VCC is the device supply voltage and the supply current is specified on the datasheet. For example, given VCC = 12 V and Supply current = 9 mA. Power dissipation = 12 × 0.009 or 108 mW.

- Power consumed in the output transistor. This value is V(on)(sat) times the output current (set by the pull-up resistor). If V(on)(sat) is 0.4 V (worst case) and the output current is 20 mA (often worst case), the power dissipated is 0.4 × 0.02 = 8 mW. As you can see, because of the very low saturation voltage the power dissipated in the output is not a huge concern.

Total power dissipation for this example is 108 + 8 = 116 mW. Take this number to the derating chart in the datasheet for the package in question and check to see if the maximum allowable operational temperature must be reduced.

Frequently Asked Questions

Q: How do I orient the magnets?

A: The magnet poles are oriented towards the branded face of the device. The branded face is where you will find the identification markings of the device, such as partial part number or date code.

Q: Can I approach the device back side with the magnet?

A: Yes, however bear this in mind: if the poles of the magnet remain oriented in the same direction, then the orientation of the flux field through the device remains unchanged from the front-side approach (for example, if the south pole was nearer the device in the front-side approach, then the north pole would be nearer the device in the back-side approach). The north pole would then generate a positive field relative to the Hall element, while the south pole would generate a negative field.

Q: Are there trade-offs to approaching the device back side?

A: Yes. A "cleaner" signal is available when approaching from the package front side, because the Hall element is located closer to the front side (the package branded face) than to the back side. For example, for the "UA" package, the chip with the Hall element is 0.50 mm inside the branded face of the package, and so approximately 1.02 mm from the back-side face. (The distance from the branded face to the Hall element is referred to as the "active area depth.")

Q: Can a very large field damage a Hall-effect device?

A: No. A very large field will not damage an Allegro Hall-effect device nor will such a field add additional hysteresis (other than the designed hysteresis).

Q: Why would I want a chopper-stabilized device?

A: Chopper-stabilized sensor ICs allow greater sensitivity with more-tightly controlled switchpoints than non-chopped designs. This may also allow higher operational temperatures. Most new device designs utilize a chopped Hall element.

Suggested Devices

Standard Allegro latches are listed in the selection guides on the company website, at Hall-Effect Latches/Bipolar Switches.

Low-power latches are listed at Micropower Switches/Latches.

Possible Applications

- Speed sensing

- Rotary encoder

- Revolution counting

- Flow meter

- Brushless motor commutation

- Anti-pinch sunroof / window lift motor commutation

Application Notes on Related Device Types

Reference: AN296067