Overcoming Heating Challenges in PCB Design with Magnetic Current Sensors

Article 2 of Next-Generation Current Measurement Series: Magnetic current sensors offer a streamlined and thermally-efficient solution to traditional current measurement methods, which significantly lowers heat production and reduces component size on PCBs, essential for compact electronic designs.

Introduction

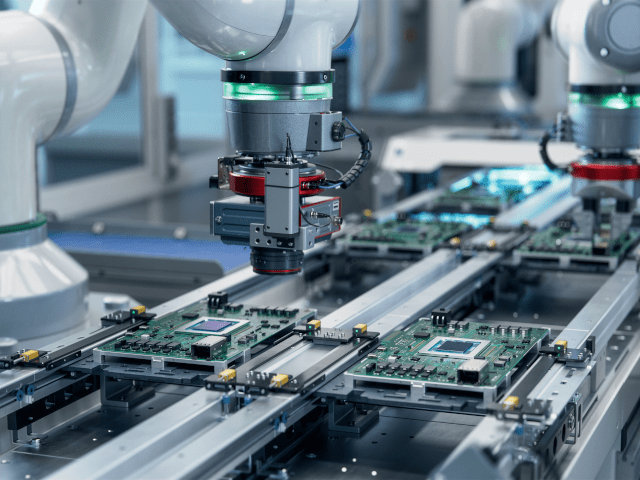

In the ever-evolving world of electronic circuits, managing heat within printed circuit board (PCB) designs has become a pivotal challenge, especially as devices shrink and demands on performance increase. Traditional current sensing methods, particularly those involving shunt resistors, often lead to significant heat generation, which can impair system reliability and performance.

Magnetic current sensors present an innovative solution to these challenges. By offering a way to measure currents with minimal heat production, these sensors help preserve the integrity of electronic systems. This article explores how magnetic current sensors can transform thermal management in PCB design, which marks a step forward in electronics manufacturing.

In our Next-Generation Current Measurement series, we previously explored various challenges associated with traditional current sensing methods. This article focuses specifically on addressing the thermal challenges within PCB design to highlight the advantages of magnetic current sensors in modern electronics.

Heat Challenges in Traditional Current Sensing Methods

Traditional methods of current measurement often rely on shunt resistors, components known for generating significant amounts of heat during operation. This heat production is primarily due to the resistance inherent in shunt resistors, where power dissipation is calculated as:

P=I2×R

At high currents, even a low-resistance shunt resistor can dissipate considerable power, thereby raising the temperature of both the resistor and its surrounding components on the PCB.

Excessive heat can lead to several adverse effects on electronic systems, such as:

- Component Degradation: Continuous high temperatures can accelerate the aging process of electronic components, which reduces their operational lifespan.

- System Reliability: Heat can cause electronic components to fail or operate unpredictably to lead to system instability and potential data loss.

- Thermal Runaway: In power-intensive applications, heat generation can lead to thermal runaway, where the system becomes unable to regulate its temperature, and causes further increases in heat and potential damage.

These challenges necessitate complex heat mitigation strategies that often involve using additional components such as heat sinks and thermal pads or choosing shunt resistors with extremely low values, all of which increase the overall cost and complexity of the PCB design. Additionally, the physical space required for effective heat dissipation further limits the miniaturization of electronic devices, a critical factor in many modern applications.

Limitations of Conventional Heat Mitigation Strategies

While conventional methods for thermal management can be effective, they come with notable drawbacks that can hinder the design and functionality of compact electronic devices:

Increased System Cost and Complexity: Implementing heat sinks and thermal pads adds to the material costs and complicates the assembly process. This not only increases the overall production expenses but also extends the time required for manufacturing and assembly.

Larger Board Requirements: To accommodate heat sinks and ensure adequate spacing for air circulation, PCBs often need to be designed with larger dimensions. This requirement runs counter to the trend towards miniaturization in the electronics industry, where reducing the size of devices is frequently a primary objective.

Aesthetic and Practical Design Limitations: Larger heat sinks and expanded PCB areas can impinge on the design aesthetics and the practicality of electronic devices, especially in devices in which form factor is crucial.

These traditional heat management approaches, while necessary for thermal control, impose significant limitations on the design and innovation potential of new electronic products.

Inadequacies of Low Resistance Shunt Resistors

To minimize heat generation, some designs opt for exceptionally low resistance shunt resistors. However, this solution introduces its own set of challenges that can adversely affect the overall efficiency and performance of electronic systems:

High-gain Amplifiers: Low resistance values typically require the use of high-gain amplifiers to produce a measurable output signal. This amplification can significantly increase the noise in the measurements, which compromises signal integrity and accuracy. High noise levels can be particularly problematic in precision applications, where the quality of data is important.

Increased Component Size and Cost: Achieving extremely low resistance often necessitates using larger or more specialized shunt resistors, which can be more expensive. This not only impacts the cost-efficiency of the design but also counteracts efforts to reduce PCB space usage.

Complexity in Design: Incorporating very low resistance shunt resistors and their associated high-gain amplifiers requires intricate design considerations. These include careful routing and shielding to prevent interference, as well as additional calibration steps during manufacturing to ensure accuracy. This complexity adds to the development time and costs, which increases the overall project timeline and budget.

As engineers seek more streamlined and cost-effective solutions, the focus has shifted towards innovative technologies that inherently avoid these complications. Magnetic current sensors represent one such advancement and offer significant benefits in terms of heat management, design simplicity and cost-effectiveness.

Minimizing PCB Heating with Magnetic Current Sensing

The adoption of magnetic current sensors presents a significant advancement in addressing the heat-related challenges of current sensing. These sensors utilize a Hall-effect-based methodology that inherently exhibits low resistance and minimal heat generation compared to traditional shunt resistors.

Comparison with Traditional Shunt Resistors

Lower Resistance: Magnetic current sensors do not rely on resistance and Ohm’s law for measurement. However, magnetic current sensors have metal leadframes for their current carrying path which possess minimal resistance when compared to most shunt resistors used in current measurement circuits. Consequently, magnetic current sensors enable significantly lower system heating—essential for designing smaller or more efficient electronic devices.

Simplified Signal Processing: The output of magnetic current sensors is directly proportional to the magnetic field and does not require the high levels of amplification needed for low-resistance shunt measurements. This reduces complexity and potential noise interference in signal processing.

These features make magnetic current sensors an attractive alternative for modern electronics, where efficiency and miniaturization are key. By integrating functions traditionally handled by multiple components into a single, compact package, these sensors not only mitigate heat generation but also improve the overall performance and reliability of electronic systems with less potential points of failure.

.jpg?sc_lang=en&hash=156346A014EB316A9E5567176C86713F)

Key Benefits of Magnetic Current Sensors

Magnetic current sensors like those from Allegro MicroSystems significantly enhance PCB designs by providing essential advantages over traditional sensing methods. These benefits are tailored to meet the evolving demands of advanced electronic systems.

Improved Thermal and Operational Performance

Minimal Thermal Impact: Magnetic current sensors operate with significantly lower heat output, which eliminates the need for complex thermal management systems and results in a cleaner and more efficient design.

Reliable Accuracy: These sensors maintain high measurement accuracy without the complications of thermal drift, which can negatively affect components subjected to high temperatures, to ensure dependable operation across various applications.

Enhanced Efficiency and Design Simplification

Integrated Functionality: These sensors combine multiple sensing functions into a single device, thereby reducing the need for additional components and simplifying the overall design.

Streamlined Manufacturing: The compact and integrated nature of magnetic sensors allows for a more straightforward assembly process to reduce both time and cost associated with manufacturing.

Cost and Space Optimization

Reduced PCB Size: By eliminating the need for ancillary components like high-gain amplifiers and heat dissipation units, these sensors allow for more compact PCB layouts.

Cost-Effective Material Use: Lower numbers of components and simplified circuit design translate into reduced material use and cost, thus making the overall product more economically viable.

Flexibility in Application

Versatile Integration: The small footprint and robust performance of magnetic current sensors facilitate their integration into a diverse range of products, particularly suitable for medium to high current applications ranging from tens of amperes in industrial systems to larger scales.

Enhanced Durability: With fewer parts and reduced susceptibility to heat degradation, these sensors offer greater durability, which is crucial for devices in harsh environments.

Case Study: European Motor Module Manufacturer

An example of the practical benefits offered by magnetic current sensors can be seen in the experience of a leading European motor module manufacturer. This company faced significant challenges in designing compact motor modules that required minimal power dissipation to maintain low system temperatures. Traditional shunt resistors were inadequate due to their high-power dissipation and led to excessive heat generation, which impacted both performance and reliability.

Challenge Faced

The manufacturer needed a current sensing solution that fit within the stringent size and thermal constraints of their compact motor designs. Traditional shunt resistors and their auxiliary components were too bulky and generated too much heat, which necessitates additional cooling mechanisms that increased both cost and complexity.

Solution Implemented

The manufacturer explored alternative technologies and ultimately chose to integrate Allegro’s ACS37220 magnetic current sensor into their designs. This sensor stood out due to its low power dissipation and compact size.

The Outcome

Incorporating the ACS37220 resulted in several significant improvements:

- Reduced Heat Generation: The lower resistance of the magnetic sensor minimized the amount of heat produced, which allowed the motor modules to operate within safe thermal limits without the need for extensive cooling strategies.

- Compact Design: The small size of the ACS37220 enabled the manufacturer to meet the compact design specifications of their motor modules.

- Cost and Complexity Reduction: By eliminating the need for additional thermal management components, the overall cost and design complexity were significantly reduced.

This successful implementation of the ACS37220 met the manufacturer's specific needs and demonstrated the magnetic current sensor's potential to transform product design by overcoming traditional challenges associated with current sensing and thermal management.

Overcoming Heating Challenges in PCB Design with Magnetic Current Sensors by Allegro MicroSystems

The Allegro ACS37220 magnetic current sensor offers essential features to effectively mitigate heating issues in electronic systems. Capable of handling high currents up to 200A, it is particularly suitable for power-intensive applications, yet it operates with significantly reduced heat generation.

.jpg?sc_lang=en&hash=83DD58CA4B34CA7FFBC38EFB6836350D)

Its compact 4x4 mm QFN package maximizes PCB space efficiency, which eliminates the need for additional cooling components such as heat sinks or fans. This benefit simplifies design and reduces overall manufacturing costs. These characteristics make the ACS37220 an optimal choice for ensuring thermal efficiency and enhancing the reliability of modern electronic systems where maintaining lower temperatures is crucial.

Conclusion

This discussion highlights the significant role of magnetic current sensors in mitigating thermal challenges within PCB design. By drastically reducing heat generation compared to traditional shunt resistors, these sensors enhance system reliability and longevity. Their continued integration is vital for advancing thermal management in electronics to ensure that as devices become smaller, they remain efficient.