Efficient and Reliable Solutions to Meet New Emission Standards in Two-Wheelers

Introduction

The increase in requirements for highly fuel-efficient, lower-emission two-wheelers is driving internal combustion engine designers to switch from carburetor-based air-fuel mixing to electronic fuel injection (EFI) systems. Designers are now challenged to find cost-effective solutions that solve the challenges of fast startup and enable reliable operation of EFI systems. This article discusses the challenges that two-wheeler designers face when switching to an EFI system, notably a 100 ms fast startup requirement. A reliable, efficient, cost-effective solution that enables quick flow of fuel to achieve the desired startup is presented. By enabling simplified designs that achieve fast startup, simplify bills of materials (BOMs), and facilitate electromagnetic-compatibility (EMC) compliance, the solution presented can improve reliability and shorten research and development time in two-wheelers.

Basics of Fuel-Mixing Systems

In an internal combustion engine, proper mixing of fuel and air in specified proportion is critical for efficiency and reliability. Low-cost two-wheelers have commonly used carburetor-based fuel mixing, but — to meet new carbon emission standards — they are being phased out in favor of the efficiency offered by EFI methods.

Carburetor systems mix air and fuel for combustion using mechanical parts, such as the fuel float chamber and the throttle venturi as well as fuel jets that spray fuel and mix it with incoming air. When the throttle of the vehicle is opened, air flow through the carburetor increases, and the venturi effect causes fuel to enter the chamber. As air flow increases, air suction increases, as does delivery of fuel, resulting in increased vehicle acceleration.

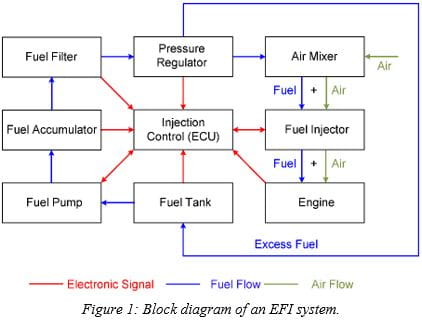

An EFI system integrates a high-speed brushless DC (BLDC) motor controlling a fuel injector that delivers fuel to the engine. An EFI system consists of electronic sensors and a fuel pump that delivers fuel to the combustion chamber located inside the fuel tank of the vehicle. The fuel supply to the combustion chamber is governed by an electronic control unit (ECU) that constantly monitors the fuel supply and precisely controls the ratio of the fuel flow based on the engine requirement. The ECU uses various parameters—throttle position, engine speed, engine temperature, and engine load, among others—for the precise and efficient control of fuel injection directly into the combustion chamber of the cylinder. A basic block diagram of an EFI system is shown in Figure 1.

The fuel pump in an EFI system draws fuel out of the fuel tank and provides it to the fuel injectors via multiple stages, as shown in Figure 1. This pump is generally driven by a BLDC motor because of its reliability, high power density, high efficiency, lower noise, lower electromagnetic interference (EMI), lower maintenance requirement, and longer life span. Unlike the traditional brushed DC motors that use brushes to transfer electrical current to the rotor, BLDC motors have permanent magnets on the rotor and electromagnets on the stator, allowing for a more efficient transfer of energy. Commutation of a BLDC motor is achieved electronically based on the instantaneous rotor position. Some systems use rotor alignment, but sensorless control of the BLDC motor system is preferred for greatest reliability.

Comparing Carburetor-Based and EFI Solutions

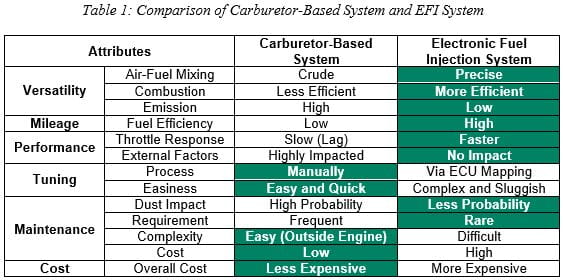

The traditional mechanical design of carburetor systems is very rugged. However, the air-fuel mixture cannot be accurately controlled, which leads to less fuel efficiency and increased emissions. Performance is also affected by ambient conditions, such as temperature. Maintenance (cleaning, adjustment, and tuning) is frequently required in a carburetor-based system, albeit this maintenance can be performed quickly and at low cost.

EFI systems are more accurate in the air-fuel-mixture ratio for a given driving condition and provide cleaner and more-efficient combustion. Also, throttle responses are quicker, and fuel economy is much better. Moreover, EFI systems are less prone to damage and therefore are generally maintenance free. However, EFI systems are typically perceived to be expensive compared to conventional carburetors, and tuning of fuel injection systems through ECU mapping is complex, which increases the cost when maintenance is needed.

Carburetor-based and EFI solutions are compared in Table 1. As two-wheeler manufacturers make the switch to EFI systems to meet new emission standards, designers are now looking to balance the new associated tradeoffs.

Speed, Efficiency, Reliability, and Ease of Tuning

Quick fuel delivery in a kick-start system critically requires quick BLDC motor startup. The efficiency of the overall system is crucial in the design. Because the device temperature is directly proportional to the power loss, minimizing power losses in the motor driver IC is also crucial. These requirements present fuel pump challenges that require an understanding of fuel pump operation.

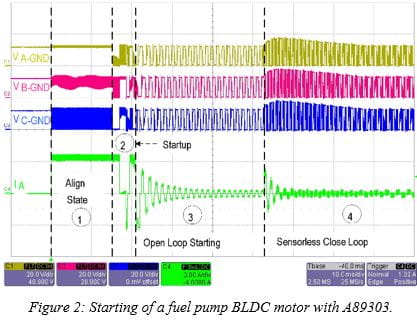

Fuel-pump startup time—from zero to full speed—typically must be as little as 100 ms. During this time, the BLDC motor must complete either a rotor alignment cycle or an initial position detection (IPD) sensorless starting cycle plus a transition to the sensorless mode. The required fast and reliable startup of a sensorless BLDC motor requires a driver that can perform the rapid IPD cycle within these requirements.

While there are many solutions available on the market today, the Allegro A89303 three-phase sensorless BLDC motor driver IC purpose-designed for fuel pump application is a fast, efficient, reliable option. An Allegro-proprietary sensorless startup algorithm is incorporated that uses a trapezoidal drive algorithm to minimize time to ramp-up to maximum speed. It ensures fuel-pump startup to full speed in typically 50 ms, as shown in Figure 2. A two-pulse IPD algorithm ensures reliable and accurate initial position detection—with low resolution (30 degrees) in fast detection time (see the A89303 product datasheet)—and assists in reducing the overall startup time of the BLDC motor. An overlapping mode adaptively adjusts (leads) the phase angle of the applied voltage. This phase leading allows efficient operation of the BLDC motor and maximizes the extraction of power from the BLDC motor. These features enable easier startup and smooth, responsive, efficient operation of kick-starters.

To meet the goals of the industry, the device needs to allow for easy tuning and protection against various fault scenarios. Many applications also require detailed diagnostics of faults. In addition to in-housing many advanced features that improve overall motor-drive efficacy—including a low on-state resistance (RDS(on)) MOSFET power stage, integrated charge pump, and I2C communication block set—the highly integrated A89303 motor driver provides fault reporting against various unwanted scenarios—such as overcurrent (motor phase short), overvoltage, undervoltage, charge-pump undervoltage, lock detection, and thermal shutdown. To allow the tuning of various electrical parameters, the I2C registers enable detailed diagnostics to be read and the I2C interface allows for ease of programming. In total, the A89303 delivers the speed, efficiency, reliability, and ease of tuning demanded by the two-wheeler industry.

Reliability with EMC Compatibility and Design Simplification

Although many motor driver ICs may be available to satisfy speed, efficiency, and tuning challenges, they typically come with significant additional development time and cost for EMC compliance, as well as complexity that reduces reliability.

Integrated devices are subject to EMI. Driver designs that place capacitor(s) and regulator(s) outside of the IC create a high-frequency emission source that results in EMI. To mitigate this noise, additional components, such as beads, are often required for EMC compliance. This is especially true in high-frequency-switching applications, such as motor drivers for fuel pumps. The additional components lead to larger, complex designs with increased development time and increased points of potential failure.

Considering the EMI challenges that arise with EFI systems, a fast, reliable, cost-effective solution likely means one that minimizes sources of high-frequency noise and facilitates EMC compliance such that development schedules are reduced, BOMs are reduced, and commensurate savings are gained.

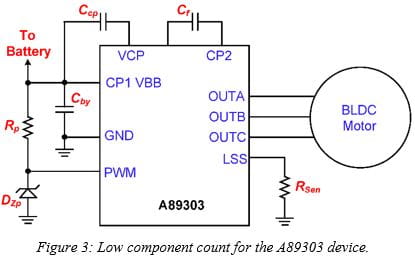

The Allegro A89303 addresses this need by in-housing the capacitor of the internal regulator, which bypasses the high-frequency switching noise of the internal digital circuitry. A spread spectrum clock in the device also minimizes EMI by spreading the emission. By bypassing and spreading the high-frequency-switching noise, systems that integrate the A89303 can earn extra margin to facilitate EMC compliance and accelerate development schedules.

BLDC motor driver operation using the A89303 requires only six passive components, as shown in Figure 3. By minimizing the number of additional components using a compact device size—the A89303 is available in the small 6.5 mm x 4.4 mm thin-shrink small-outline package (TSSOP) and the smaller 5 mm x 5 mm quad-flat no-leads (QFN) package—a smaller PCB can be used to realize a smaller, more-efficient, cost-effective solution.

The High-Performance, Cost Balancing Solution

To meet changing emission standards, many two-wheeler system designers now face the need to switch from carburetor-based systems to EFI systems. Many purpose-designed features make the Allegro A89303 motor driver IC an ideal solution for fuel pump applications, including fast and accurate startup, efficient optimization, integrated protection features, fault handling, and ease of programmability.

Based on the article, "Efficient and Reliable Solutions to Meet New Emission Standards in Two-Wheelers" by Vashist Bist and Shashank Wekhande, originally published in Circuit Digest, June 5th, 2023. Republished with permission. For portions not copyrighted by original publisher, Copyright ©2023, Allegro MicroSystems, Inc.

Copyright 2023, Allegro Microsystems.

The information contained in this document does not constitute any representation, warranty, assurance, guaranty, or inducement by Allegro to the customer with respect to the subject matter of this document. The information being provided does not guarantee that a process based on this information will be reliable, or that Allegro has explored all of the possible failure modes. It is the customer's responsibility to do sufficient qualification testing of the final product to ensure that it is reliable and meets all design requirements.

Copies of this document are considered uncontrolled documents.